In terms of modern day production, the precision and effectiveness of laser slicing know-how are genuinely activity-altering. Laser chopping devices have revolutionized industries by furnishing a method of slicing supplies with unparalleled precision. When you’ve at any time marveled within the intricate types on steel or puzzled how complex styles are generated so seamlessly, it’s generally the work of an industrial laser reducing equipment.

Let’s start with the basic principles: a laser cutter is really a Resource that takes advantage of a laser beam to cut resources. This beam is exceptionally targeted and generates substantial temperatures to soften or vaporize the material, generating exact cuts. Not like traditional techniques, which might use mechanical blades, a laser cutter provides a standard of accuracy that is almost unmatched. Picture wanting to carve a fragile pattern by using a hammer—clearly, a laser cutter is a good deal a lot more refined!

Industrial laser slicing can take this technology to the next stage, delivering answers for big-scale functions. These equipment are crafted to deal with hefty resources and large output volumes, guaranteeing that even quite possibly the most demanding jobs are completed with high efficiency. Think of it as being the distinction between employing a precision knife for sensitive paper crafts and a strong observed for reducing by thick Wooden.

What Does Industrial Laser Cutting Mean?

In the world of CNC laser chopping, the “CNC” stands for Computer system Numerical Handle. This technological know-how allows for automated and hugely exact cuts by pursuing electronic types. In case you’ve at any time utilised a pc to attract and after that noticed that drawing arrive at lifestyle, CNC laser chopping is effective in an identical way, translating electronic styles into physical cuts. It’s like using a virtual designer with the precision of a laser.

In the world of CNC laser chopping, the “CNC” stands for Computer system Numerical Handle. This technological know-how allows for automated and hugely exact cuts by pursuing electronic types. In case you’ve at any time utilised a pc to attract and after that noticed that drawing arrive at lifestyle, CNC laser chopping is effective in an identical way, translating electronic styles into physical cuts. It’s like using a virtual designer with the precision of a laser.Laser Cutting Equipment Fundamentals Explained

Precision laser cutting isn't just about making cuts; it’s about generating them right each and every time. The laser is usually modified to obtain diverse depths and widths, guaranteeing that every Slice is strictly where it needs to be. This is often vital for applications wherever even a slight deviation could lead to significant issues. Think of it for a surgeon’s scalpel, exactly where precision is not simply vital but Certainly essential.

Precision laser cutting isn't just about making cuts; it’s about generating them right each and every time. The laser is usually modified to obtain diverse depths and widths, guaranteeing that every Slice is strictly where it needs to be. This is often vital for applications wherever even a slight deviation could lead to significant issues. Think of it for a surgeon’s scalpel, exactly where precision is not simply vital but Certainly essential.Laser slicing products comes in numerous sorts, Each and every tailored to specific requires. No matter whether You'll need a little desktop product for passion projects or a large industrial equipment for factory use, there’s a laser chopping Resolution to choose from for you personally. These equipment vary in electric power, pace, and abilities, so it’s imperative that you pick the proper one in your specific application.

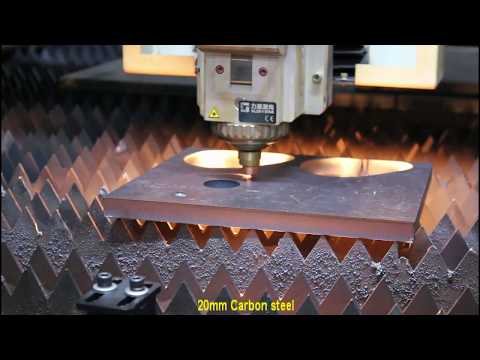

Sheet steel laser cutters really are a special classification of laser chopping devices built especially for chopping steel sheets. They may be broadly Employed in industries ranging from automotive to aerospace due to their power to manage metal with precision and speed. Picture a sheet of metal like a blank canvas, plus the laser cutter since the artist who makes complicated and exquisite designs with remarkable precision.

Laser reducing products and services are A different important element of this technological know-how. Not All people requires to take a position in their own laser chopping equipment, especially if they only need to have occasional cuts or deficiency the Room for these types of tools. Quite a few businesses offer laser reducing companies where you can mail your patterns and possess them Reduce with superior precision. It’s like outsourcing your artwork to a skilled Experienced.

Laser chopping methods integrate several factors to deliver the desired effects. In the laser source on the slicing mattress, as well as Manage program, every single Section of the process operates collectively to make sure a flawless Procedure. It’s a little similar to a symphony orchestra, where by Each and every musician has a certain role, and only by Functioning alongside one another do they make a harmonious performance.

In terms of laser slicing technological innovation, the evolution has been immediate and impressive. In the beginning employed generally for slicing metals, these machines now deal with an array of components which includes plastics, wood, and in many cases fabrics. This versatility tends to make laser reducing technological know-how a useful tool in plenty of industries. Think about possessing a Swiss Army knife which can tackle virtually any product—this is what modern day laser cutting engineering provides.

The precision of laser slicing devices is actually impressive. They are able to Reduce products to within just microns with the intended layout, guaranteeing that even one of the most intricate details are preserved. This degree of precision is especially precious in industries wherever exact measurements are essential. Think about it given that the distinction between a tailored suit and off-the-rack clothes—the in good shape is just fantastic each time.

The Single Strategy To Use For Sheet Metal Laser Cutter

One more benefit of laser cutting technological know-how is its efficiency. Compared with traditional reducing methods Which may involve multiple steps or instruments, laser reducing often completes the endeavor in one go. This not merely hurries up creation and also decreases content waste. It’s like possessing a higher-speed practice that receives you to the location speedily and effectively with no unneeded stops.While in the context of industrial purposes, the robustness of laser chopping equipment is important. These machines are created to endure the requires of constant operation, normally functioning 24/seven in superior-quantity options. Their durability guarantees steady overall performance and reliability, that is important for protecting creation schedules. It’s like possessing a heavy-obligation truck that reliably provides merchandise working day following working day.

Among the list of impressive areas of laser chopping is its ability to create clean and specific edges. This visit site decreases the need for put up-processing, for example sanding or ending, which may be time-consuming and costly. The end result is actually a sleek, completed product or service That usually necessitates minimum extra perform. Visualize ending a craft job with no glue spills or rough edges—it’s that thoroughly clean!